Differential Rings (Friction Rings)

- Offers various types of differential rings (friction rings), such as bearing type, bakelite type, key type, ball type, etc.

Categories: Differential Rings (Friction Rings), 套夾(卡盤)

🚀Product Description

NIIKA differential rings (friction rings), also known as slip rings, are critical components for industrial web handling machines (such as slitting, rewinding, coating, laminating machines and other take-up shafts). They are specifically designed to address issues like wrinkles, breaks, or deviations caused by uneven material tension and linear speed differences during the winding process. As a key part of the differential shaft, their core function lies in a self-regulating differential compensation mechanism through friction. This dynamically adjusts the speed difference of each roll in response to variations in material thickness, tension requirements, or rotational speed, achieving consistent linear speed and constant, controllable tension. They are widely used in precision slitting and winding operations for plastic films, printing, packaging, textiles, and other materials.

🚀Product Features

- Made with high-strength, wear-resistant materials and special processes, these differential rings (friction rings) offer exceptional durability, significantly extending service life, reducing maintenance and replacement costs, and are suitable for long-term continuous operation.

- Differential rings (friction rings) enable precise control of web tension and automatically compensate for speed differences, preventing material stretching or tearing. This ensures consistent winding quality and significantly improves product yield.

- Suitable for various web handling machines such as slitters, rewinders, and coating machines. Compatible with a wide range of web materials including films, paper, fabrics, and metal foils. Widely used in printing, packaging, textiles, electronics, and other industries.

- Offers customized design services to accommodate different machine specifications and material characteristics, meeting specific tension control requirements, optimizing production efficiency, and enhancing competitiveness.

🚀Product Specifications

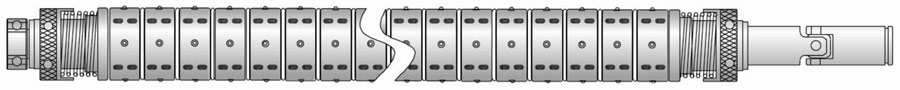

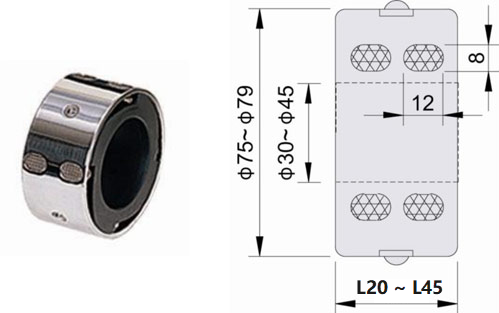

▌NEG 110K (Key Type, Bakelite Type)

▌NEG 110SB & 110B (Ball Type, Bearing Type)

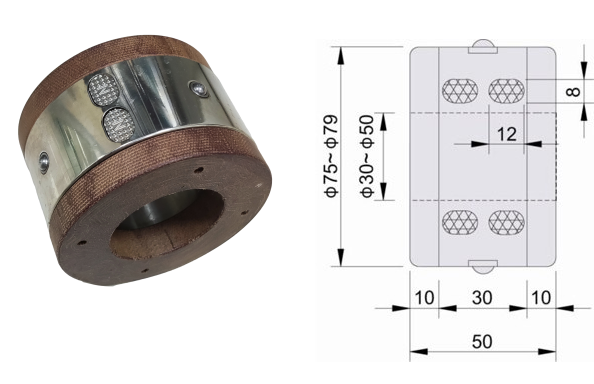

▌NEG 210K (Key Type, Double-sided Bakelite)

🚀Product Applications and Ordering Information

Please specify the following when ordering:

- Maximum load capacity

- Application (slitting size)

- Key dimensions or drawings