- Home

- 產品介紹

- Tension Controller

- Tension Controller

Tension Controller

Categories: Tension Controller

🚀Product Description

Tension controllers are automated control systems used in industrial production processes to monitor and adjust material tension. They ensure that web materials (such as: films, paper, metal foils, photographic films, fabrics, wires, non-woven fabrics, etc.) maintain constant tension during winding, unwinding, or conveying processes, preventing problems such as deformation, wrinkles, and breakage caused by excessive or insufficient tension, thereby ensuring product quality and production efficiency.

🚀Product Features

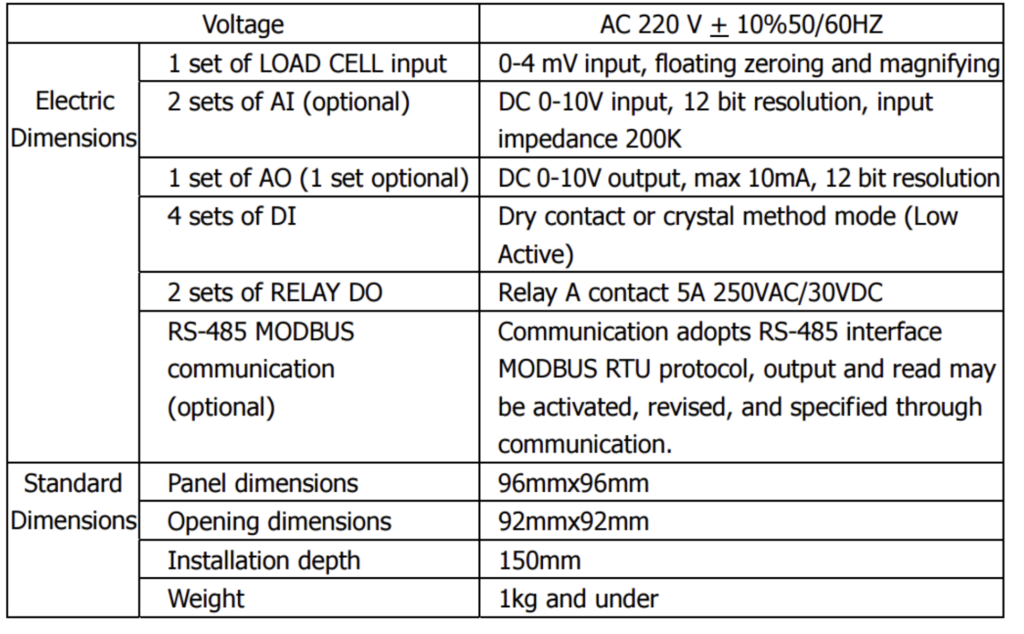

▌Feedback Tension Controller TC-608P

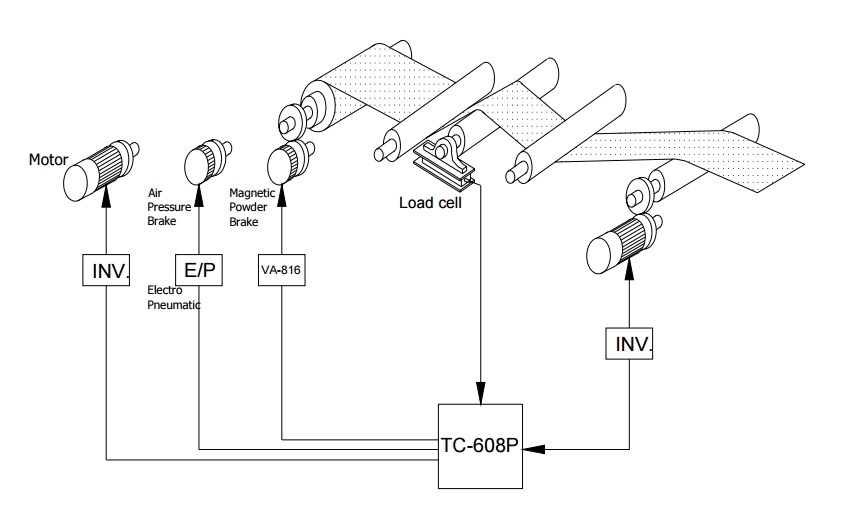

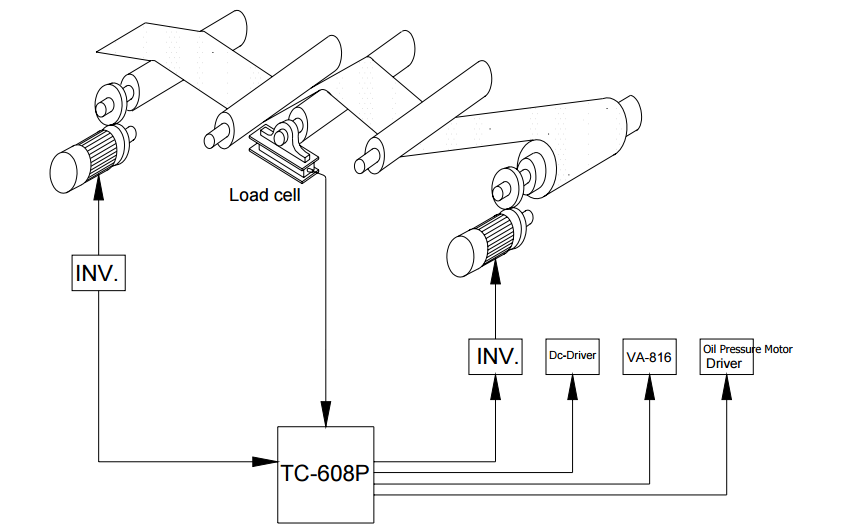

TC-608P is a high-precision tension controller designed for winding and unwinding applications on production lines. It compares the preset tension value with the actual tension value fed back by the LOAD CELL sensor, automatically calculates and corrects the output command, and precisely controls the braking force or winding torque.

- High Precision and Reliability: Provides stable and reliable tension control, ensuring production quality.

- Customizable Tension Units: Tension value units can be set to kg, N, or LB as required.

- Direct Load Cell Input Support: Digital zeroing and magnification adjustment for easy operation.

- Multi-function Display: Simultaneously displays tension setting value, actual tension value, and output command.

- Master Speed Acceleration/Deceleration Gain Delay: Features acceleration/deceleration gain and delay time output adjustment functions that follow changes in master speed.

- Power-off Memory: Equipped with parameter power-off memory function, eliminating the need for resetting.

- Startup Compensation: Startup gain function compensates for mechanical static friction to ensure smooth startup.

- Stop Tension Optimization: Stop tension discount function to prevent excessive tension during stops.

- RS-485 Communication: Supports RS-485 communication interface, allowing connection to PLC and PC for system integration.

⋅ Input/Feeding/Unwinding (Put in)

⋅ Winding/Take-up/Reeling (Roll up)

▌Fully Automatic Tension Controller HS-808

Comprehensive Tension Applications: Integrates unwinding, winding, and intermediate section tension control needs, suitable for magnetic powder clutches/brakes (magnetic particle brakes) or various torque drivers, widely used in paper making, printing, packaging, textiles, and other industries.

Stable Control Core: Built-in digital line speed proportional linkage and multi-stage PID algorithm to ensure stable tension performance during startup, acceleration/deceleration, stopping, and speed changes.

Intelligent Tension Adjustment: Features linear or multi-stage Taper (attenuation) function, and can automatically compensate for inertia during acceleration/deceleration and stops for precise control.

Dual Direct Drive Outputs (DC 24V/4.5A): Can directly and powerfully drive magnetic powder clutches/brakes (magnetic particle brakes), eliminating the need for external amplifiers, and enabling automatic shaft change for passive unwinding.

Dual General-Purpose Voltage Outputs (DC 0-10V): Can directly control torque controllers, current control type vector inverters, DC motor controllers, and servo motor drivers, with output signals definable by parameters (tension value/current roll diameter/second shaft output).

Wide Sensor Compatibility: Supports single/dual tension sensors, compatible with commonly used bridge type (e.g., micro-displacement) or dedicated type (e.g., Mitsubishi LX series) tension detectors, and can also receive 0-2KΩ resistance signals for Dancer control implementation.

Multiple Input Interfaces: Offers 2 sets of analog signal inputs (automatic/manual tension/Taper setting) and 6 sets of programmable digital inputs (e.g., shaft change, start/stop, tension cut-off, and other auxiliary functions).

Precise Roll Diameter Detection: Capable of receiving Encoder A-phase pulses and roll proximity signals for internal calculation, or external analog voltage can be designated as the roll diameter signal source via parameters.

Convenient Operation and Calibration: Features dual displays (LED main display + LCD auxiliary display), providing digital one-key zeroing and a simplified calibration process by inputting the kilogram value of the input sensor.

Industrial Communication Integration: Integrated RS485 communication function for easy connection with PLC programmable controllers, Human-Machine Interfaces (HMIs), industrial computers, and other systems for online control and data exchange.