- Home

- 產品介紹

- Electromagnetic Brake

- SAB Electromagnetic Fail-Safe Brake (Safety Brake …

SAB Electromagnetic Fail-Safe Brake (Safety Brake / De-energized Brake)

- Safety Brake (Fail-safe brake), Negative Action Electromagnetic Brake

Categories: Electromagnetic Brake, Electromagnetic Clutch/Brake

🚀Product Description

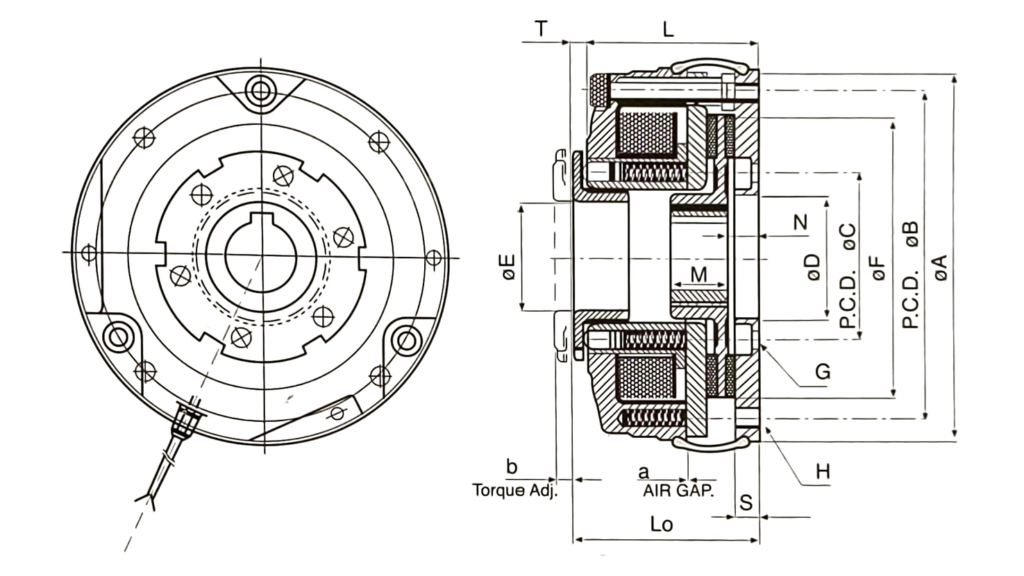

The SAB Series Electromagnetic Fail-Safe Brake (Safety Brake / De-energized Brake) is a high-performance, highly reliable industrial-grade safety braking solution. As a Fail-Safe Brake (De-energized Brake), its core design concept is to utilize the pressure of the built-in spring to generate braking force when power is off. This ensures that in the event of a power outage or emergency, mechanical equipment can be immediately and safely stopped or held stationary, effectively preventing accidents. When power is applied, the electromagnetic coil generates suction to release the brake, allowing the equipment to operate normally.

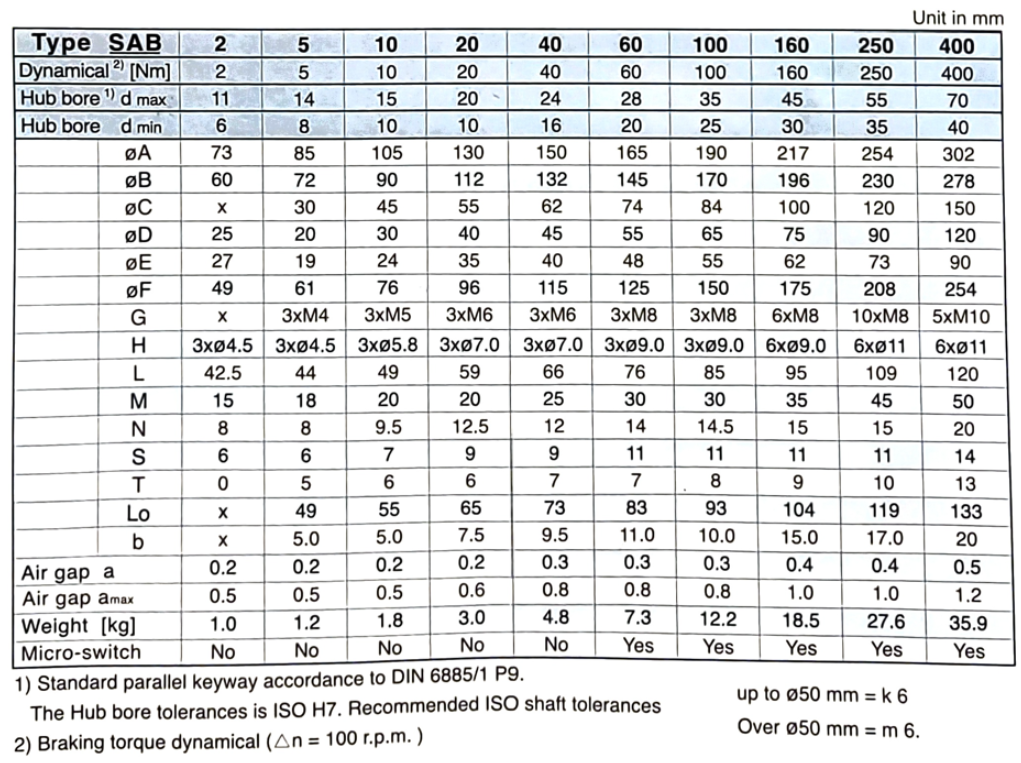

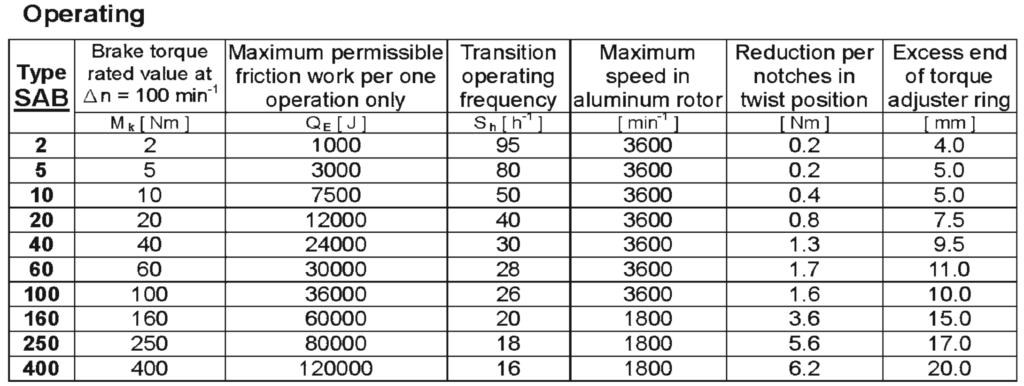

This series of brakes is designed for dry operation, using selected low-wear, non-asbestos friction materials (brake pads / brake linings / friction pads / brake blocks), combined with a nitrided armature and a fully encapsulated coil to ensure the product has excellent durability and long service life. Its sophisticated structural design allows it to absorb a large amount of energy during dynamic braking (dynamic brake) and is also ideal for static long-term holding applications. SAB brakes offer a wide torque range (2 Nm to 800 Nm) and provide a variety of standard voltage options (such as 24V, 96V, 190V, 205V DC, and can also accept special customization from 6V to 240V DC).

🚀Product Features

- Core Safety and High Reliability: Built-in Fail-Safe mechanism to ensure absolute safety during power outages; manufactured and tested in accordance with ISO 9002 and DIN VDE 0580 international standards for stable quality.

- Easy Installation and Low Maintenance: Preset air gap design simplifies installation steps for quick assembly; robust structure and wear-resistant components effectively reduce subsequent maintenance frequency and costs.

- Rich Options and High Customization: Offers diverse configurations, including manual release device (lateral option available), multiple voltage selections (6-240VDC), low noise design, special mounting flange/hub bore, and corrosion protection.

- Quick Response and Precise Control: Quick release armature design ensures sensitive brake response, combined with dry friction transmission, enabling precise motion control for both dynamic braking and static holding.

🚀Product Specifications

▌SAB