You are here:

- Home

- 產品介紹

- Safety Chuck (Safety Chucks)

- Safety Chuck (Safety Chucks)

Safety Chuck (Safety Chucks)

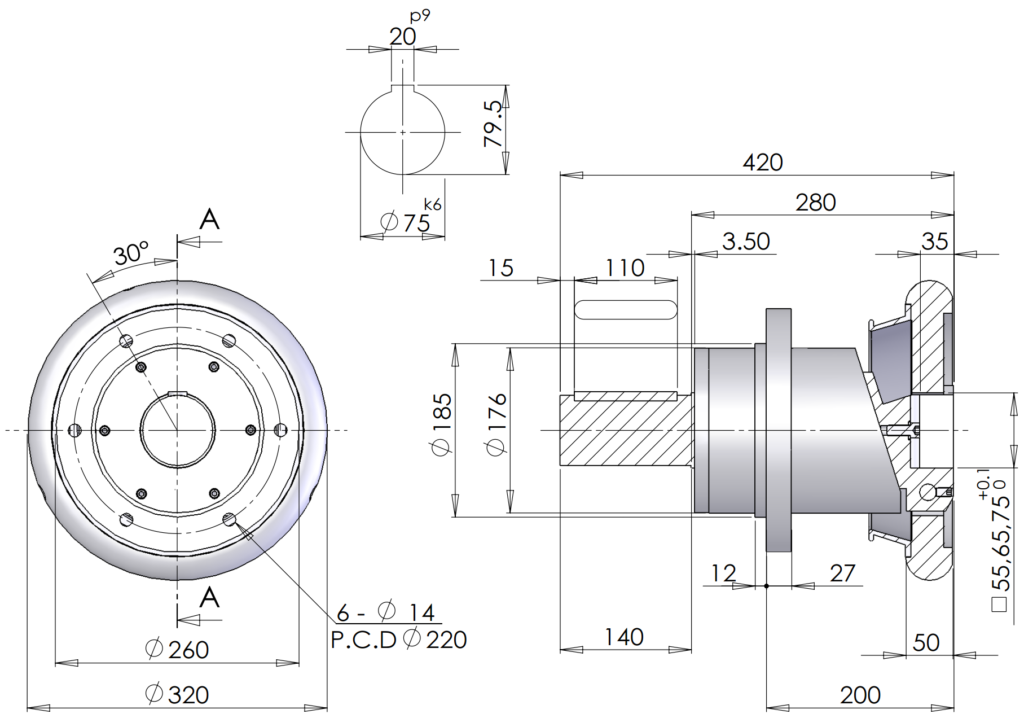

- Model PIO/W is compatible with STO/W.

- Drive shaft and journal dimensions can be customized to your requirements.

- VT-type inserts are also available; please contact us for details.

- Can be used in combination with the ESBM manual brake or the NAB pneumatic through-shaft brake (air brake).

Categories: Safety Chuck (Safety Chucks)

🚀Product Description

- Safety Chucks are critical components in industrial roll-to-roll (Roll-to-Roll) equipment. Often paired with air shafts (airshafts / air mandrels) or tubes to engage and disengage drive transmission, they provide a firm and reliable clamping force. Widely used in industries such as printing, packaging, film, plastics, rubber, and textiles, they effectively reduce downtime during production. These devices feature quick-change capabilities and ensure the stability and precision of web material transport, significantly boosting production efficiency.

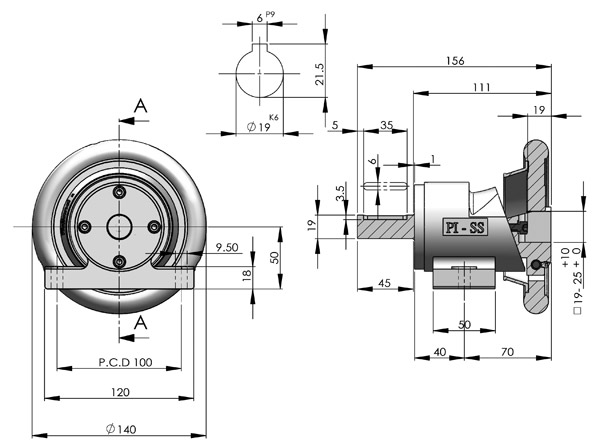

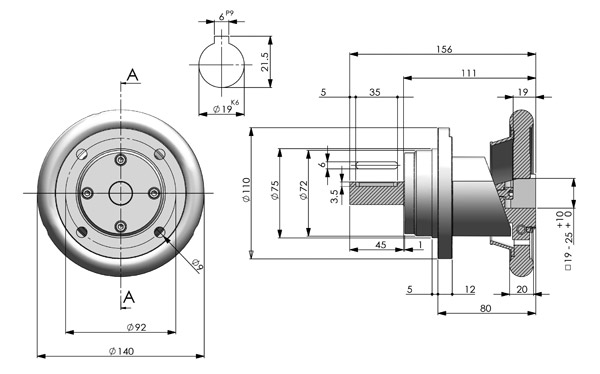

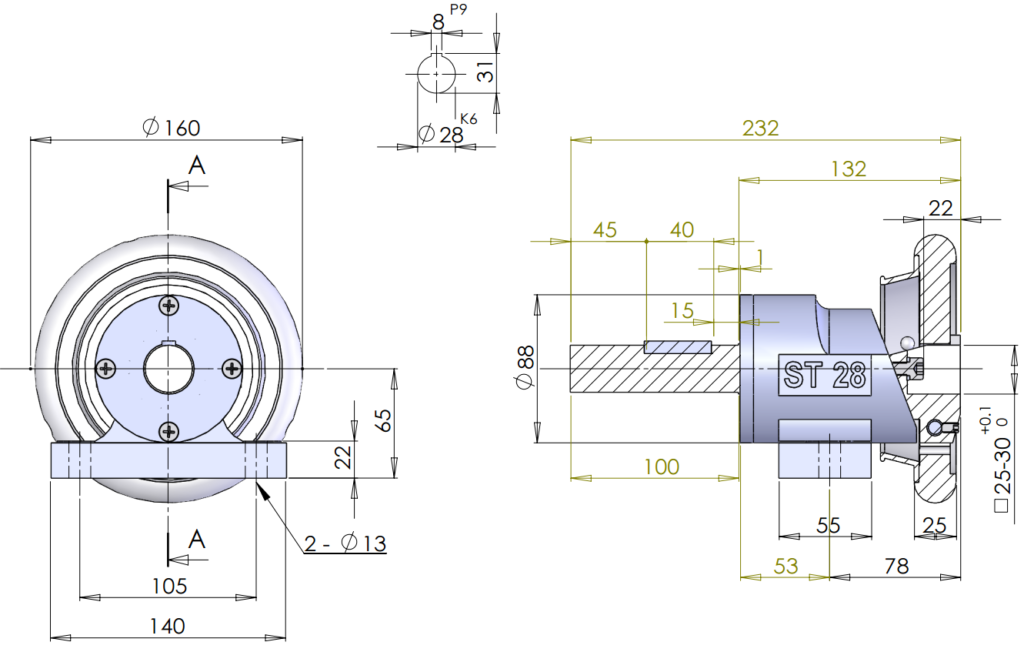

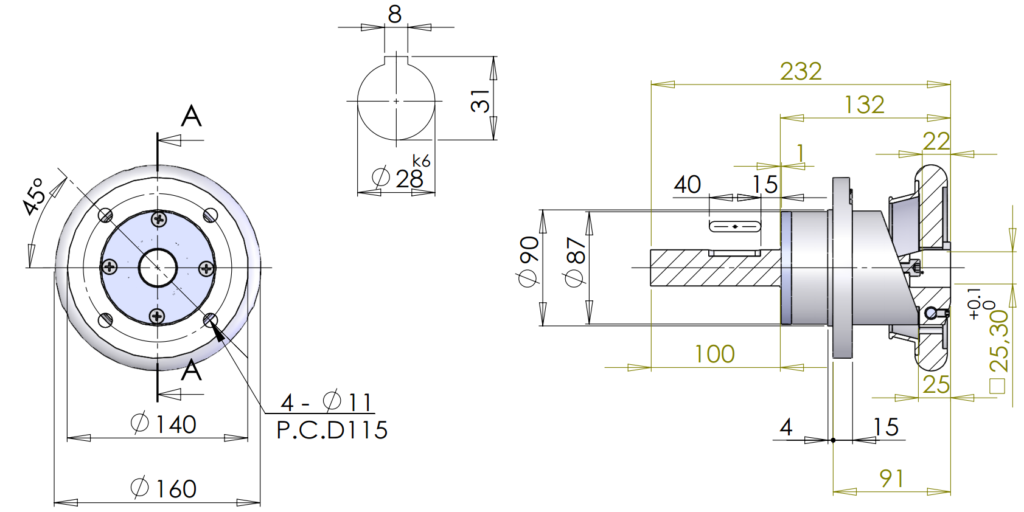

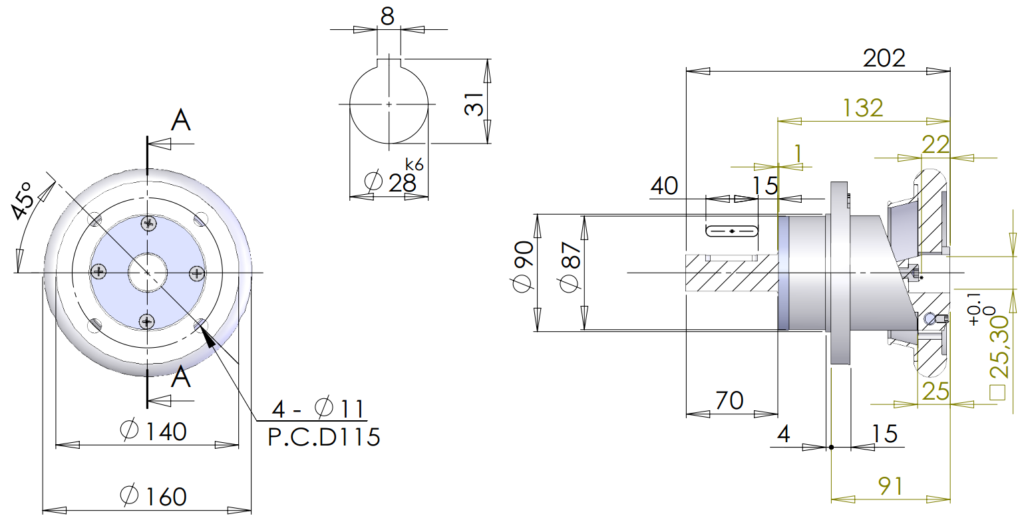

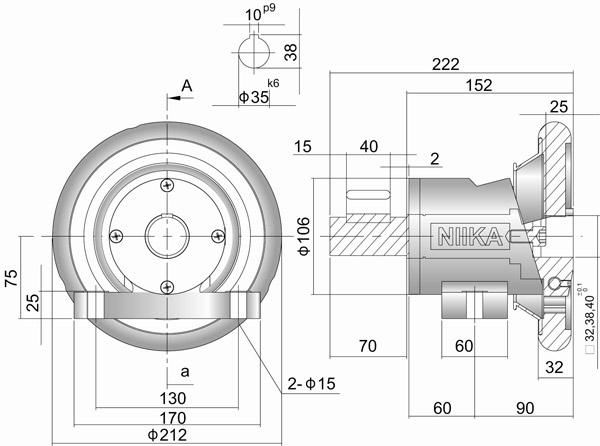

- They are typically classified by mounting style into flange-mounted (FLO, FLW) and pillow-mounted (PIO, PIW) types. ‘W’ designates a model with a drive shaft, while ‘O’ indicates a model without one.

The standard journal is square (C-type), but different journal shapes are available and can be customized to your specifications.

🚀Product Features

- Efficient and secure roll-to-roll handling solution for stable material clamping.

- Reduce downtime and boost production efficiency.

- Prevent roll slippage to improve operational safety and minimize accidents.

- High-rigidity design ensures stable material transport.

- Offers a wide range of specifications and configurations for diverse industrial applications.

🚀Product Specifications

| Model | Max. Load (kg) | Max. Torque Allowed (kgf·m) | Standard Square Bar Size (mm) | Unit Weight (kg) | Standard Shaft Diameter (Ø) x Length (mm) |

|---|---|---|---|---|---|

| PIO/W SS(19) FLO/W SS(19) | 300 | 12 | 19-25 | 9 | Ø19 x 45 |

| PIO/W S(28) FLO/W S(28) | 800 | 18 | 25-30 | 18 | Ø28 x 100 |

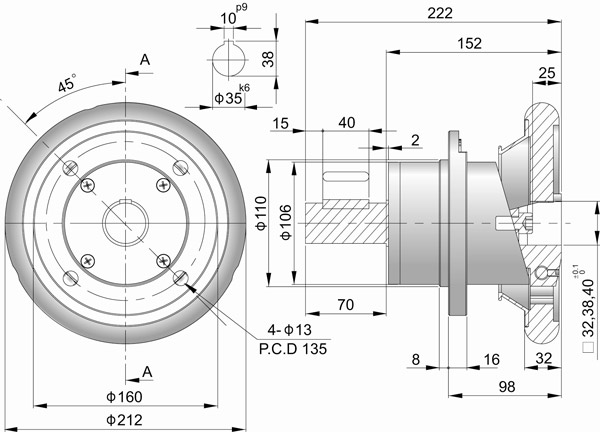

| PIO/W M(35) FLO/W M(35) | 1600 | 35 | 32-40 | 27 | Ø35 x 70 |

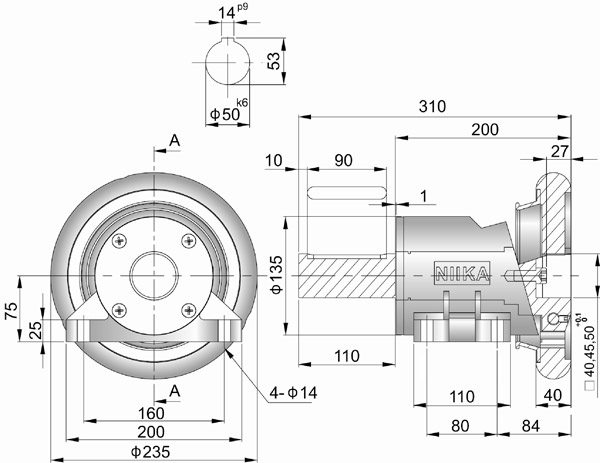

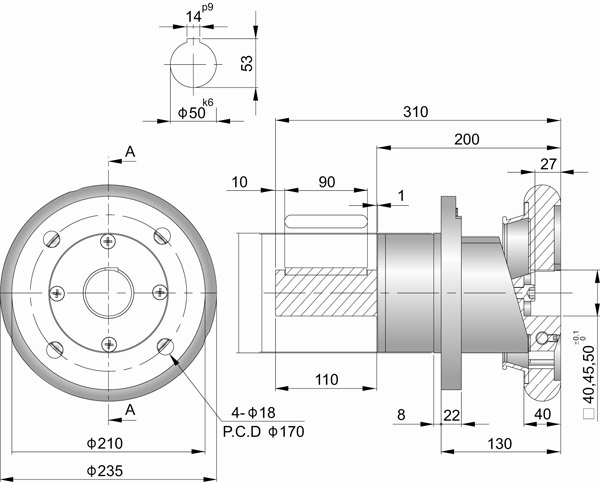

| PIO/W L(50) FLO/W L(50) | 2800 | 110 | 40-50 | 53 | Ø50 x 110 |

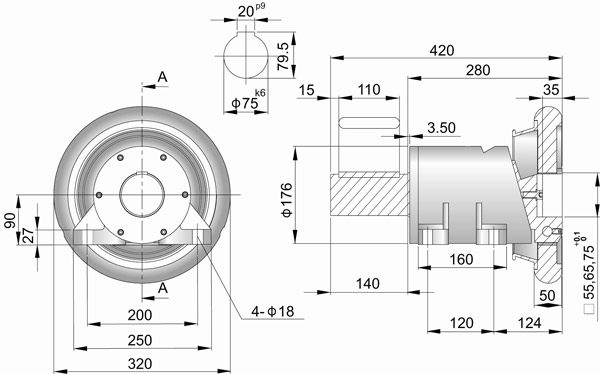

| PIO/W XL(75) FLO/W XL(75) | 7000 | 235 | 55-75 | 120 | Ø75 x 140 |

🚀Application Combinations

PIW / FLW + NAB

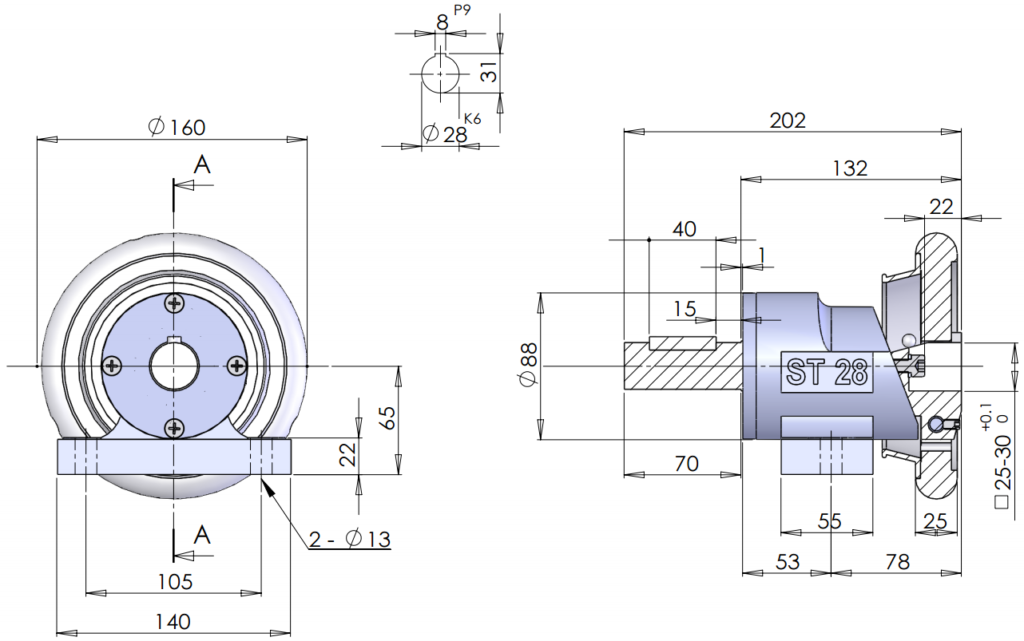

In roll-to-roll processing equipment, the combination of PIW/FLW Safety Chucks and NAB pneumatic brakes (air brakes) is ideal for unwinding, jogging, and tension control. This setup is perfectly suited for industries like printing, film, plastics, packaging, and textiles, ensuring high-precision roll material handling.

The integrated design of this combination allows for direct assembly of the chuck and brake. This not only reduces installation space requirements but also enhances the equipment's stability and operational flexibility, leading to a smoother, more precise, and efficient production process.

PIW M(35) + ESBM

Combined application of Safety Chuck PIW M(35) and Manual Brake ESBM.